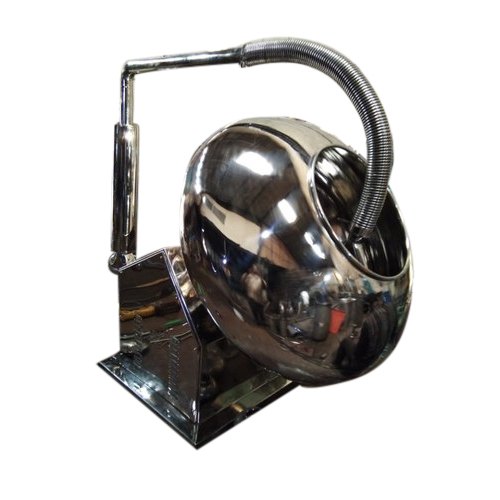

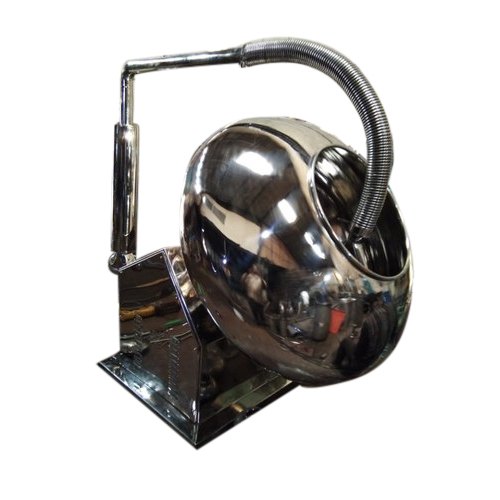

Standard Coating Pan

Conventional coating machine are used to sugar coat tablets, pills, etc in for a variety of industries such as Pharmaceutical, Confectionery, Food and others. They are also used for rolling and heating beans and edible nuts or seeds.

The product is to be filled inside the pan. During the rotation motion, coating material is sprayed byspraying system according to the technological process and rational technological process. So processmaterials (product) are coated due to rotating pan. The coating round pot is rotated by variable speed. At the same time hot air is supplied through inbuilt Hot air blower system which dries rapidly (heating or cooling) and evenly thus forming a solid and smooth surface.

Standard coating pan, which is also known as the conventional pan system is a popular accessory in most pharmaceutical industries.

Basically, the design of this type of tablet coating machine is such that there is a circular metal pan whose diameter may range from 6 to 80 inches (15 to 200 cm). The pan is slightly tilted to an angle of about 45°C to the bench top.

A hot medium reaches the shelf through the inlet header and flows through the shelves in a uniformly zig-zag pattern ensuring faster heat transfer to the surface. This in tam heats up the trays on the shelves. The hot medium flows out from the shelf through the outlet header.

Technical Specification of Tablet Coating Pan, Tablet Coating Machine

| Model |

CP-24' |

CP-36' |

CP-48' |

CP-60' |

CP-72' |

| Loading capacity |

25 |

60 -80 |

100-120 |

150-200 |

250-250 |

| Drive Motor HP 3 PH 50 C S 415 V AC line |

0.50 |

1.00 |

2.00 |

5.00 |

7.5 |

| RPM of Pan (empty) |

24 / 72 |

12 / 36 |

10 / 30 |

8 / 24 |

5/10 |

| Hot air blower motor HP 3 PH 50 C/S 415 V AC line |

0.25 |

0.50 |

1.00 |

1.00 |

1.00 |

| Blower capacity Maximum CFM |

100 |

200 |

500 |

750 |

750 |

| Heater K.W |

1.5 K.W |

3 K.W |

4.5 K.W |

6 K.W |

6.K.W |

Vacuum Tray Dryer is used mainly for drying of high grade, temperature and oxygen sensitive products. Vacuum Tray Dryer is highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pomposity.

Vacuum Tray dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door. Inside are several heating plates mounted one above the other on which the product is placed in trays.

The bottoms of both heating plates and trays should be as smooth as possible to permit optimal heat transfer between plates and product.

The medium flowing through the heating plates is water, steam or thermal oil. Vacuum Tray Dryer

The distance between the heating plates is determined primarily by the surface loading and thefoaming of the product.

To avoid retrograde condensation the cabinet walls are indirectly preheated by the heating plates. Next, the product is introduced and heated at atmospheric pressure. Only after all individual product trays reach the same temperature the cabinet is evacuated and drying can start.

The preheating phase is very important in order that the drying curve and the foaming of the product is identical throughout the cabinet.

During the main drying phase the vacuum is in the range of 40 to 80 mbar abs and in the final drying phase vacuums of only few mbar abs are reached.

Heating temperatures are normally in the range between 800C and 1100C. Depending on product and surface load, drying takes from a few hours to 1 to 2 days.

For some products the vacuum and temperature profiles are automatically controlled in order to prevent a pass over of the critical product temperature.

The dimensioning of the vacuum system is an important factor in the design of drying cabinet systems. If for example vigorous foaming of the product is desired, evacuation to the operational vacuum level must take place very quickly.

Vapours produced during drying are taken out direct, or via a steam jet compressor to a surface condenser in which the vapours condensate. The non-condensable vapours are extracted by the vacuum system.

On completion of the drying, the product can be cooled by circulating of cooling water through the heating plates.

Often vacuum drying cabinets are supplied to new, small production operations in newly opened markets. Following successful development of the market, it could be worthwhile to replace the cabinets through continuous vacuum belt type dryers.

*Specification can be changed as per customers requirements